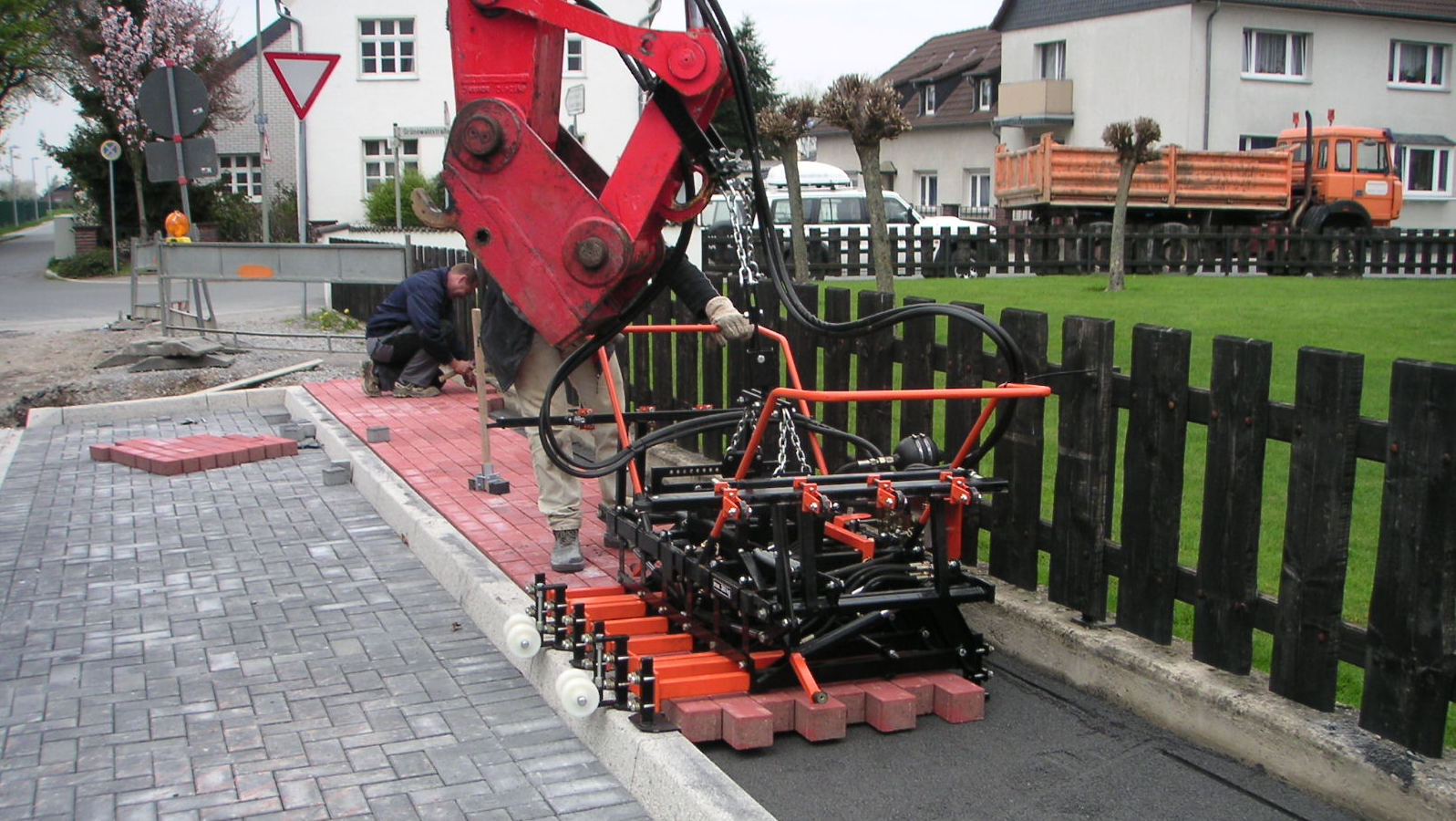

- Suitable for "one-man operation" - no further assistance required

- Swing stop suspension for easy handling

- 3-K control prevents accidental opening of the paver clamp

- Very gentle picking up and placing of stones

Product information "Paver-Clamp Multi6 M for various carrier (e.g. Excavators, Wheel loaders)"

There are so many different concrete pavestones available on the market, that it is no longer possible to keep track.

This raises the question, whether a single paver clamp is sufficient for the countless types of pavers & slabs with their different thicknesses and package sizes? Our clear answer: Yes! Whilst other manufacturers rely on providing up to five or more different models, we have designed one single clamp system to meet all your possible needs. Can infinitely be adjusted to all stone formats, stone layers and stone thicknesses in a few simple steps.

These are your advantages:

NEW 2020

- A new desgin enables even more power when pressing and shifting the stones.

- Paving stones can be placed right up to sidewalls.

Multi-talented

- Paver-Clamp can be connected to the Paver Laying machine or to any carrier device

- Stone layers from 0.6 m² (6.5 ft²) to 1.5 m² (16 ft²) can be handled without problems

- Clamps thin stones with 40 mm or thick stones with 240 mm, light stone layers with about 130 kg (280 lbs) or voluminous heavy duty stones with e.g. 550 kg (1.200 lbs) own weight

- Uneven stone layers are picked up by the clamp in exactly the same way as smooth stone layers

- Moves stones from cross bond into running bond by shifting every second row, even with stones who have a protection against disloction

- Herringbone patterns with or without half stones can be handled without problems

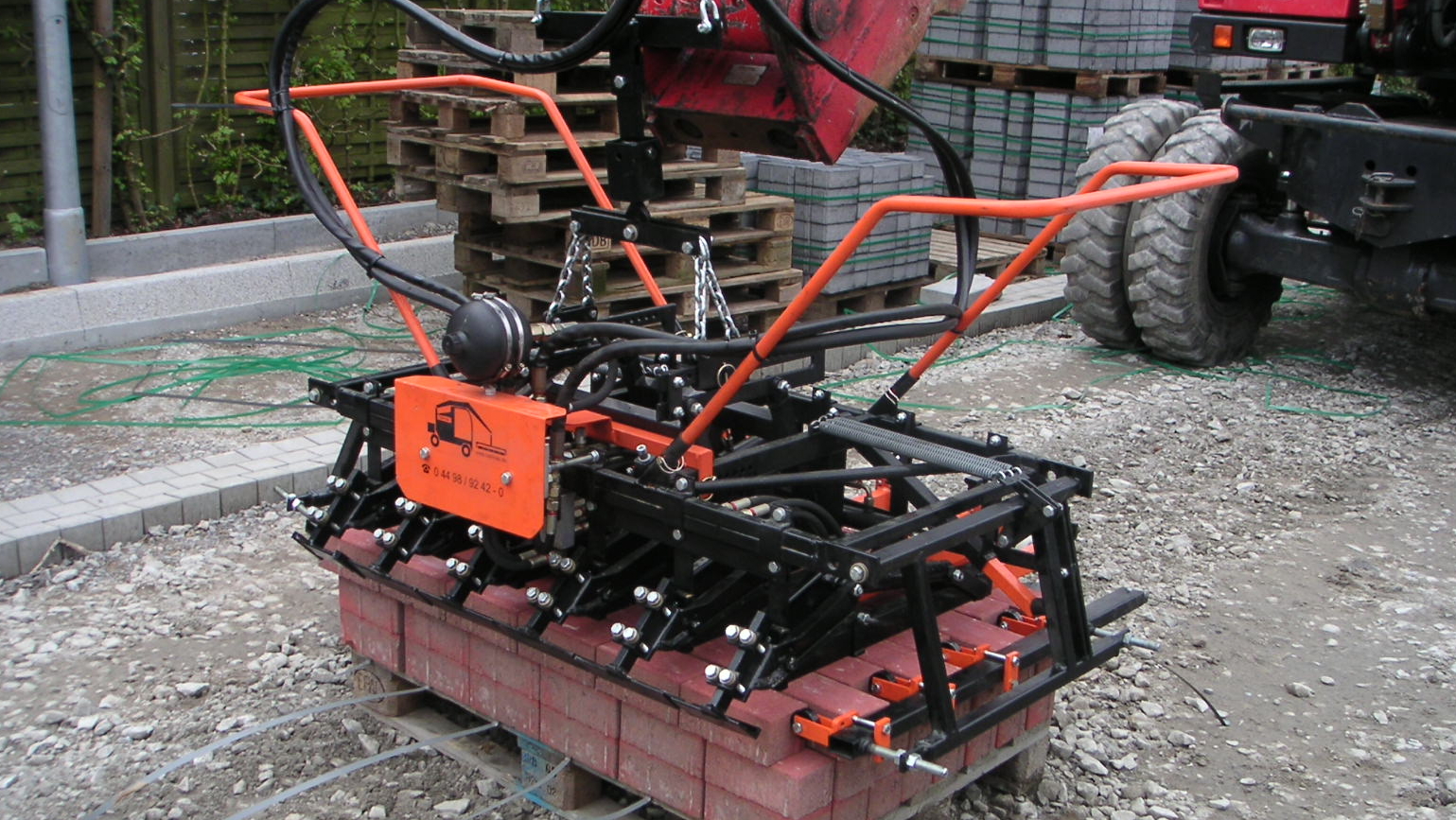

- Also clinker or clay bricks, which are stacked on pallets in a read-to-be-laid arrangement, can be clamped in a gentle way.

Easy handling

- The operator can carry out the laying work without further assistance.

- Swing-stop suspension - easy to handle even for inexperienced operators

- With 3-K control, accidental opening of the Paver-Clamp with stones is impossible.

Intelligent technology

- Also available for carrier with only one available hydraulic circuit.

- Additionally available with SMART control 3 K (Patent Nr. 20 2018 103 859.1)

Including rotator the operator can control 3 hydraulic functions separately

with only 2 available hydraulic circuits. - Hydraulic Tap-down-device as a standard for a perfect joint pattern.

Individual options

- Endlessly working hydraulic turning gear (Rotator)

Universal connection options

- Easy mounting on all common construction machines (hydraulic excavators, wheel loaders ...

Material-friendly

- Only 60 bar hydraulic pressure is required due to the intelligent 6-arm clamping technology. Means, safe clamping as well as very gentle to the stones.

This results into a pavement with a perfect joint pattern - this is the distinguishing feature, compared to all other grabs on the market.

Optimal expandability

- A later mounting to an Optimas laying machine is possible without any problems.

The success and experience show: Many of the Optimas paving clamps have already laid several 100,000 m² (1.000.000 ft²) of pavers without any problems. Solid workmanship and the advantage of "Made in Germany" production.

It is worth comparing price and technology before making a purchase decision: Optimas definitely offers the best price/performance ratio!

In three work steps to the perfectly laid pavement:

Basic configuration:

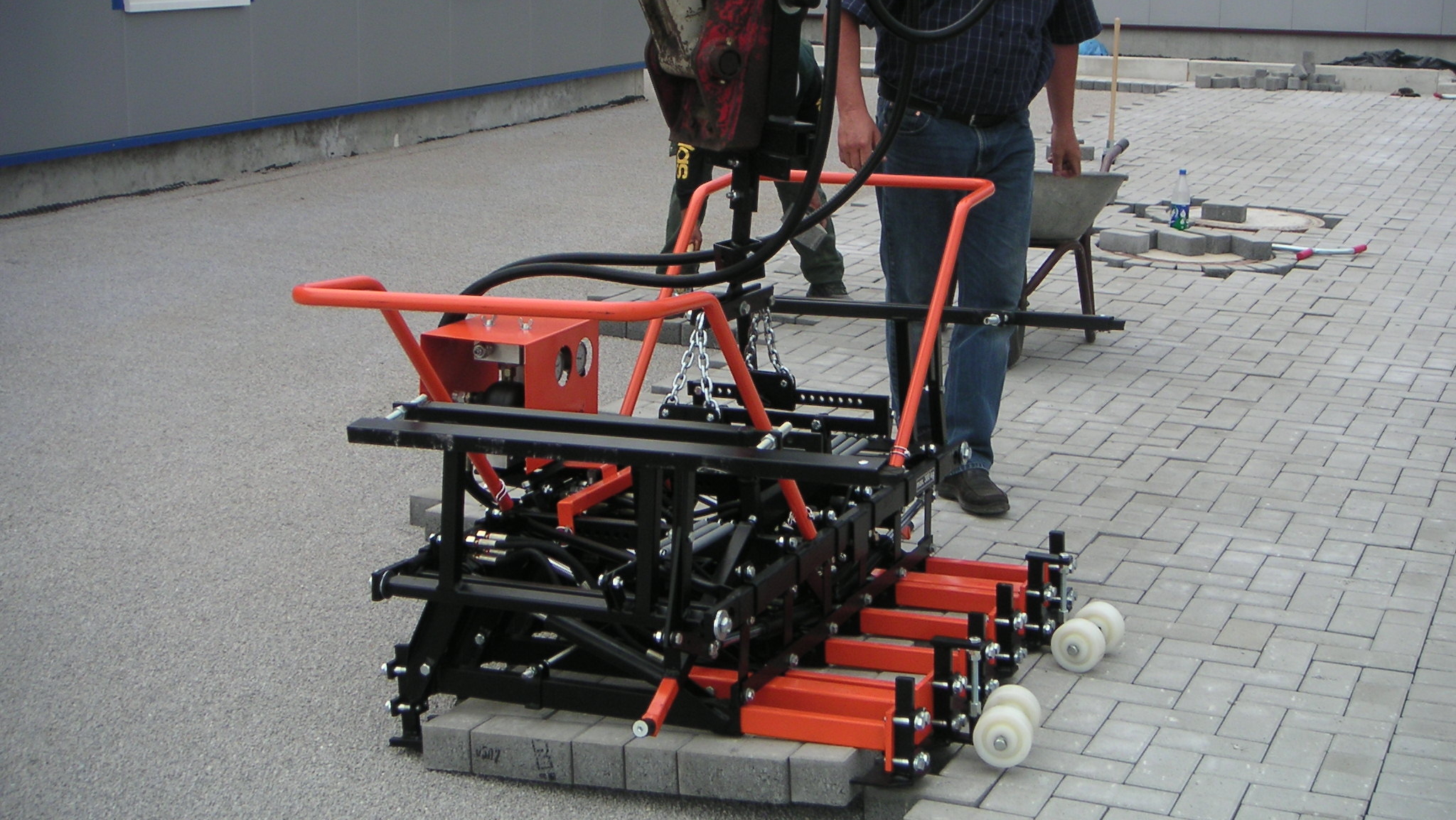

- Intelligent 6-arm clamping technology

- Hydraulic Tap-down-device for clean joint pattern

- Swing-Stop Suspension

- Hydraulic hoses to the carrier

- Hydraulic couplings to the carrier

- Universal connecting device

- Alignment / shifting pieces

95% of all concrete paving stones are laid with the standard equipment. The following points should/will be clarified in advance with the potential user to ensure the Paver-Clamp is properly equipped.

- Stone manufacturer

- Stone formats

- Laying patterns

Optional features

-

3K-SMART control – rotator & smart valve

(Patent No. 20 2018 103 859.1)

Including rotator the operator can control 3 hydraulic functions separately with only 2 available hydraulic circuits.

1. Rotator - Endlessly working hydraulic gear for turning the Paver-Clamp

2. Lateral aligning/shifting

3. Clamp function open/close -

Endlessly working hydraulic turning gear (Rotator)

- Quick-change mounting (suitable for individual carrier)

Available variants:

- Paver-Clamp Multi6 M 3K-SMART control including Rotator (carrier e.g. excavator has two available hydraulic circuits) - as described above

- Paver-Clamp Multi6 M 2K (carrier e.g. excavator has two available hydraulic circuits) – the lateral aligning/shifting and opening/closing functions are controlled separately

- Paver-Clamp Multi6 M 1K (carrier e.g. excavator has only one available hydraulic circuits) - the lateral aligning/shifting and opening/closing functions are automatically controlled in sequence

- Paver-Clamp Multi6 M 1K LIGHT version (15 % less weight compared to a standard Paver-clamp) (for light carrier e.g. Mini-Excavator 1.7 to (3.700 lbs) - depending on the carrier device, a chassis widening or a counterweight ensures sufficient stability.

Which variant is suitable for the user depends, among other things, on the carrier device. This point should be clarified in a consultation with Optimas.

In our instruction videos, we explain to you how to adjust the Paver-Clamp correctly and safely.

First watch the instruction videos and then start working.

Optimas Paver-Clamp Multi6 M:

| Hydraulic pressure "Gripping": | 60 bar |

|---|---|

| Own weight: | 185 kg (408 lbs) - depending on equipment the weight increases |

| Package sizes: | 0.6 m² (6 ft²) to 1.5 m² (16 ft²) |

| Stone thickness: | 40 mm to 240 mm |

| Stone weight: | up to 550 kg (1.212 lbs) |