- the world's most modern paver laying machine

- ergonomic

- economical

- powerful

- new features

Product information "Paver Laying Machine PaveJet S24"

Our paver laying machine has been on the market since 1978, and it's been looking for its equal ever since. As is often the case with originals, they don't get better by copying. They only get better through continuous further development in the spirit of the inventor. Our Optimas engineers have modernised the machine technically, and our product designers have given it a fresh look.

We have also made sure to take customer wishes into account and change, modernise and make more comfortable further details.

The majority of our Paver Laying machines are manufactured order-related, so that the respective customer requirements such as clamp options and extras like e.g. cabin, heating, 4-wheel-drive or even an individual painting can be integrated into the production process.

The PaveJet S24 installs pavers and slabs extremely fast and precise with a perfect joint pattern.

No matter whether on small or large construction sites, the perfect combination of the 2-axle turntable steering and the endless grab turning gear means that the machine is always optimally usable. Whether laying in underground car parks or picking up stone layers from pallets on top of each other with a height of 2.60 m - there is no limit.

You can confidently put the issue of staff shortage away. The PaveJet S24 is a reliable employee who quickly becomes popular and pays off.

All new features at a glance:

- New design

- Control bar replaced by 7” display: Clear view of everything now. This is especially helpful when you are working in the underground garage or picking up from a height of 2.5 m (like two stone packs on top of each other).

- New control unit / 7” display

The central control unit for all functions, including the reversing camera. As standard, the operator can set three driving modes - Basic, Standard and Special. - Hydraulic clamp pressure can be adjusted.

This enables material-friendly and fuel-saving work.

Error message - Errors in the hydraulic system are signalled and assigned. - Chassis and boom

This machine is less than 2 metres high, making it perfect for underground car parks. There is no need to dismantle any parts. - Air conditioning: Ensures a pleasant working environment in the cab even when high outside temperatures.

- New sound system

Radio with DAB, Bluetooth, USB and hands-free system. High-quality loudspeakers are mounted on the rear wall at head height in the cab. - New motor: The PaveJet S24 is equipped with a performance-optimised Kubota engine, which offers a higher torque and therefore more power. Even under maximum load, e.g. with all-wheel drive and running air conditioning, the power limit is not reached. In normal paving situations, it can be operated at low engine speeds, which contributes to a fuel-efficient driving style.

- Despite the increase in performance the PaveJet S24 remains authorised for low emission zones, as the engine output is less than 19 kW.

There are lots of reasons why the PaveJet S24 is a great choice:

- simple operation and the open design

- Revised hydraulics - three driving modes are available. Basic, Standard, Special. Every operator can find their ideal setting

- New control unit / 7” display

- all steel parts powder-coated (very resistant and durable).

- front panel, side panels and bonnet made of glass fibre reinforced plastic (high strength, UV-resistant, weatherproof and rustproof)

- user-friendly, a high-quality work result can be effortlessly achieved also after an 8-hour working day.

- agile due to the proven geometry

- stable and mobile even with a high shift of the centre of gravity

- short-term amortisation of the investment - long operating life of the S19 PaveJet

- enormous effectiveness for contractors - very motivating for the worker.

- The PaveJet S24 is fast... with optimum site organisation, it installs the pavers in 20-second cycles.

- Installation of more than 1000 m² (10.000 ft²) per day possible

Also available with pure ELECTRIC DRIVE: PaveJet S19E

For information on the PaveJet S19E , click here.

Basic Edition:

- Paver-Clamp Multi6 M, find detailed information here

- Hydraulic Tap Down device on Paver-Clamp for a perfect joint pattern

- Control unit / 7” display

- The central control unit for all functions, including the reversing camera.As standard, the operator can set three driving modes - Basic, Standard and Special.

- Continuous clamp rotation gear

- Automatic: all clamp functions are performed automatically

- Joystick

- Semi-automatic

- Steering column, adjustable

- Foot pedals adjustable

- Seat adjustable

- 4-cylinder Diesel engine (Kubota V1505)

- (Engine below 19 kW - trouble-free operation in low emission zones)

- hydrostatic drive

- 2-axle turntable steering

- Storage space/board tool kit

- Painting: All steel parts powder coated. Front panel, side parts and bonnet made of glass fibre reinforced plastic (pure orange)

- LED headlight package (1 front light, 2 working lights and 1 reversing light) incl. daytime running light

- LED warning beacon

- Mobile phone holder

- Bottle holder

- 12 Volt connection + USB charging socket

- Central lubrication

- Hour counter, cycle counter

- Revolution counter

- Wide tires

A detailed description of the basic equipment can be found in this overview here.

Exclusive Edition (Standard Edition + following equipment)

- Cabin: Front windscreen can be opened. Safety glass all round, doormat.

- Heating with 2-step blower

- Two-stage boom – work in the underground car park and clamping of 2 packages.

- Sound system: Radio with DAB, Bluetooth, USB and hands-free system, 2 loudspeakers

We offer the following package (only available with Exclusive Edition)

- Comfort seat with air suspension and heating.

- Radio with Bluetooth hands-free unit.

- Heatable outside mirror

In addition we offer optional:

-

Air conditioning: ensures a pleasant working environment in the cab.

- Special painting (Painting in all RAL colours possible. On request, we will be pleased to supply in your company colour)

- Joystick - Steering

In addition to the steering wheel. Integrated in the left armrest.

Easy and intuitive to use. Steering wheel removable.

The display allows the user to select from three different steering characters

See video here - Joystick for "lifting / lowering" function

In addition to the foot pedal. Integrated in the right armrest.

The " lifting/lowering" function can be controlled by both the foot pedal as well as the joystick.

See video here - Permanent all-wheel drive incl. anti-slip, switchable

- Particulate filter (complies with TRGS554)

- Rear view camera incl. 7" monitor

- Reversing signal

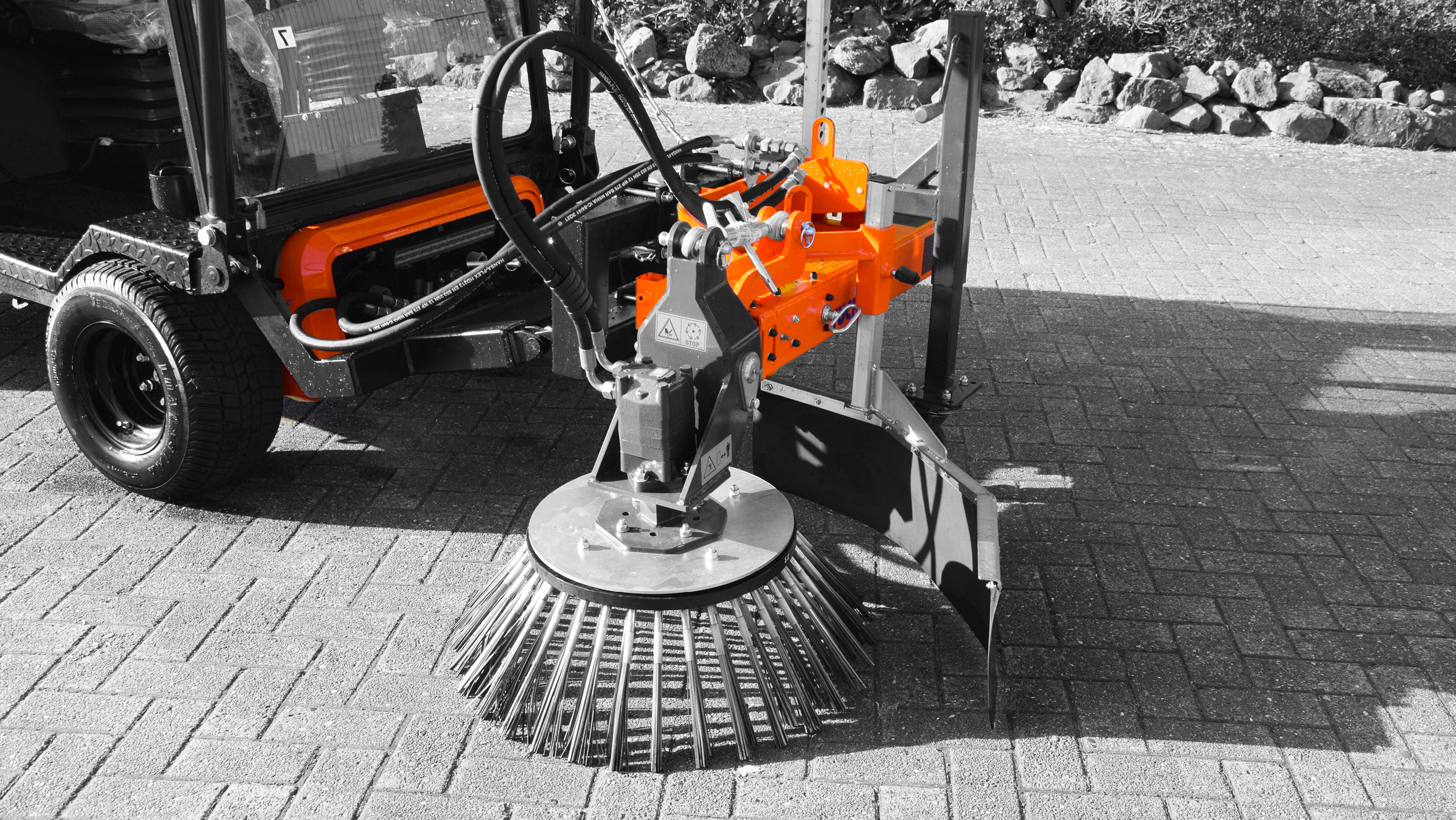

- Additional hydraulic connection (for e.g. Clean Sweeper)

- Loading lugs

A detailed description of the optional equipment can be found in this overview here:

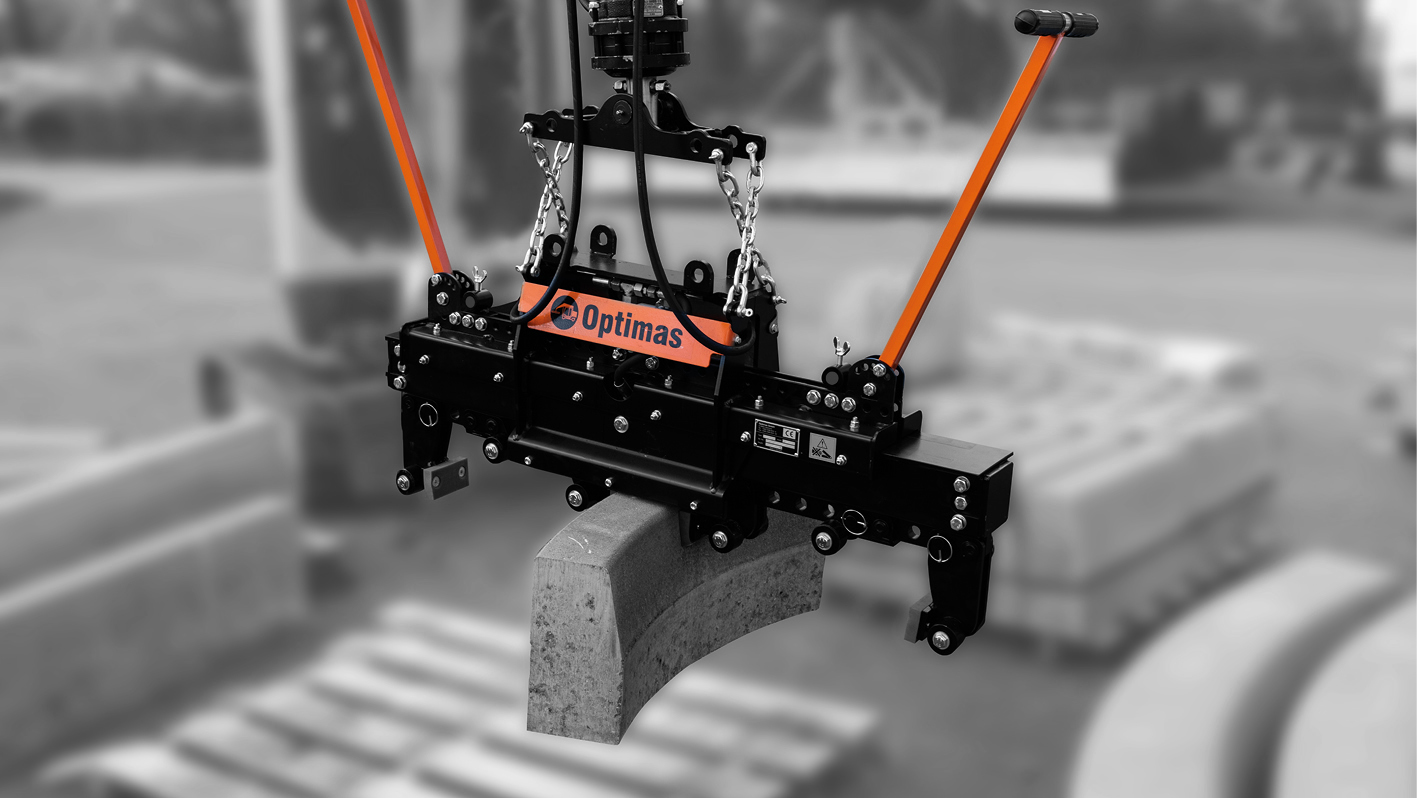

The Paver-Clamp Multi6 M is part of the standard equipment. It can be infinitely adjusted to all stone formats, stone layers and stone thicknesses.

Find detailed information to our Paver-Clamp Multi6 M here.

In our instruction videos, we explain to you how to adjust the Paver-Clamp correctly and safely.

First watch the instruction videos and then start working.

Optimas Paver-Clamp Multi6 M:

| Height: | 1.990 mm |

|---|---|

| Length: | 4.000 mm |

| Load capacity: | 700 kg (1.540 lbs) |

| Motor: | Kubota Diesel engine, 4-cylinder, water-cooled with electric ventilation, 18.5 kW (25 hp), soundproofed. Meets EU Stage V and TIER IV final (USA) exhaust emission regulations, no restriction in low emission zones as engine power < 19 kW. |

| Other: | Oil cooler; hydrostatic drive with single-pedal control, 2-axle turntable steering, rear axle with independent pendulum suspension, parking brake , Steel and aluminium parts powder-coated. Front panel, side panels and bonnet made of GFK-parts. Colours: RAL 2004 (pure orange), RAL 9005 (deep black). CE - marked, Tank 45 l Diesel |

| Weight: | starting at 1.490 kg (3,285 lbs) depending on configuration |

| Width: | 1.430 mm |